Now Reading: Accurex Introduces BendingStudio XT for Seamless Integration and Advanced Workflow Automation in Tube Manufacturing

-

01

Accurex Introduces BendingStudio XT for Seamless Integration and Advanced Workflow Automation in Tube Manufacturing

Accurex Introduces BendingStudio XT for Seamless Integration and Advanced Workflow Automation in Tube Manufacturing

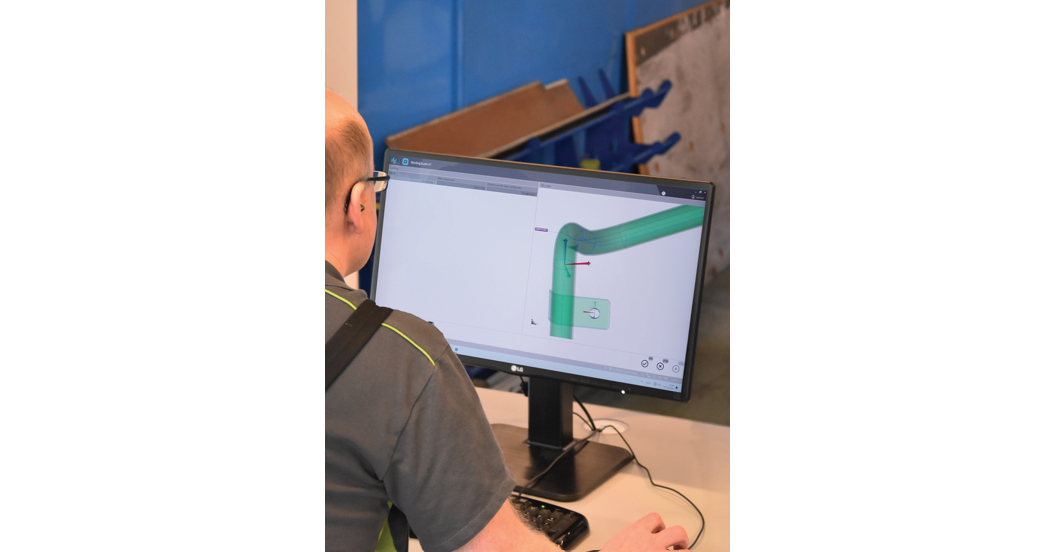

Accurex has introduced BendingStudioXT, a cutting-edge software designed to streamline tube bending processes and seamlessly integrate with the new 2025 TubeInspect system. This software revolutionizes tube manufacturing workflows by allowing real-time optimization and correction of parts, reducing waste, and ensuring consistent production quality.

As industries face increasing pressure to enhance speed, precision, and efficiency, BendingStudioXT equips manufacturers with the necessary tools to achieve tighter tolerances while maintaining high throughput. By integrating directly with CNC bending machines and offering automated feedback for corrections, this innovative software simplifies the tube manufacturing process and boosts the return on investment for manufacturers.

Key features include real-time closed-loop integration, automated workflow optimization, an intuitive interface, and advanced diagnostics and feedback. This software is particularly beneficial for industries like aerospace, automotive, and eMobility where precision and efficiency are crucial.

Bill Mongon, President of Accurex, stated that BendingStudioXT complements the 2025 TubeInspect system, aiming to reduce errors and maximize production output. The software is part of their vision to transform tube manufacturing processes and keep customers competitive in a rapidly evolving market.

The 2025 TubeInspect system is now available for ordering through Accurex Measurement. For more details, visit their website. Contact Jamie Brown, Marketing Specialist at Accurex Measurement, via email at info@accurexmeasure.com or by phone at (610) 544-1006.

Accurex Measurement, headquartered in Swarthmore, PA, offers optical measurement and inspection solutions to help manufacturers achieve exceptional quality and efficiency. Specializing in advanced metrology, visual inspection, and automation, Accurex remains at the forefront of innovation in manufacturing.